Battery Recovery

Waste electrical batteries must be recovered and not disposed of as many people believe. We live in a world where resources are limited and environmental pollution is a growing threat to our planet.

It is imperative that we adopt practices that promote sustainability and reduce our ecological impact. That is why recovery should be at the centre of our waste management strategies.

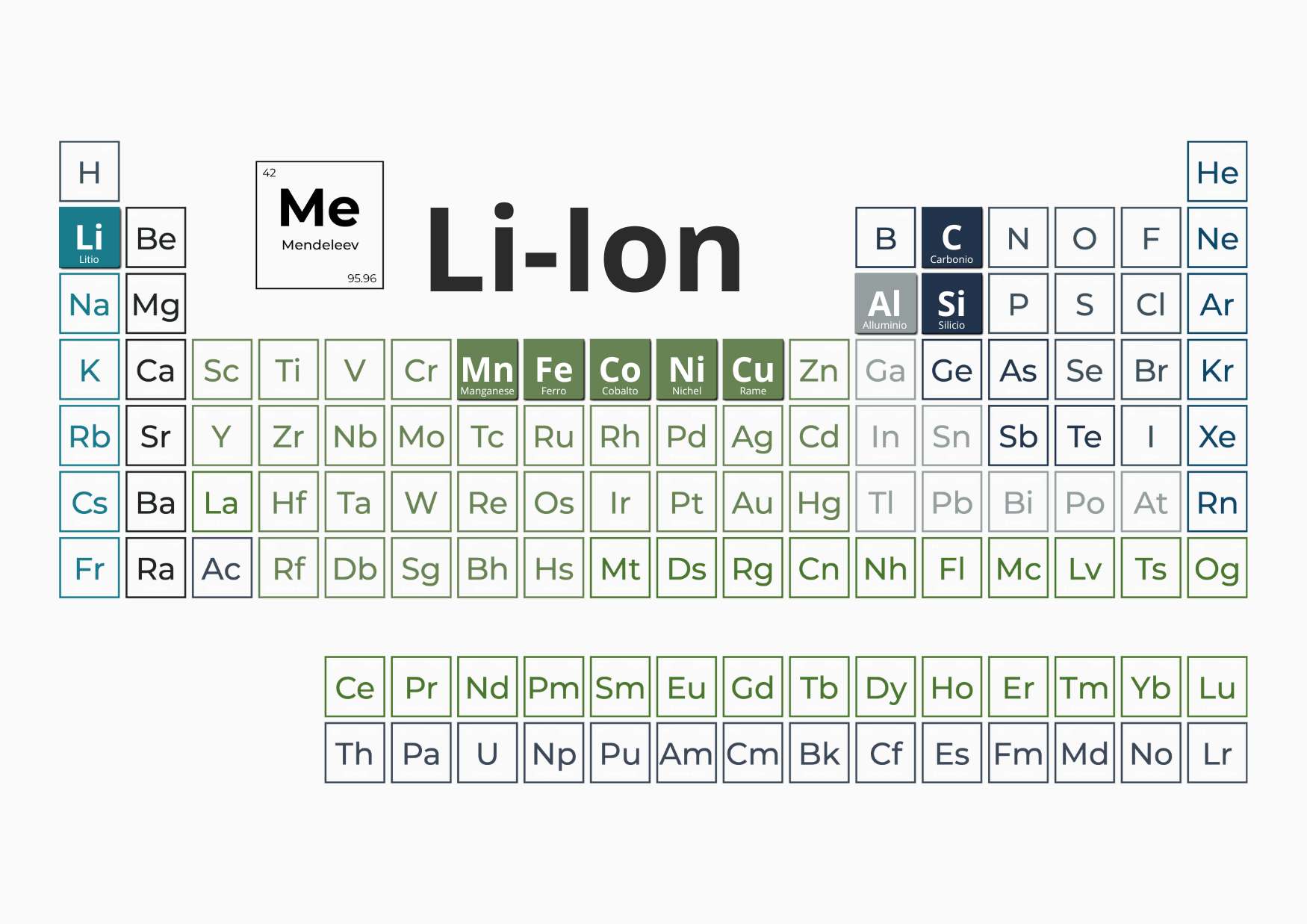

Li-Ion battery recovery

The recovery of lithium-ion batteries is an important process to ensure sustainable resource management and reduce environmental impact. Lithium-ion batteries are widely used in a variety of electronic devices, electric vehicles and rechargeable energy storage systems.

Lithium-ion cells contain valuable materials such as lithium, cobalt, nickel and other metals. Recycling these batteries allows these materials to be recovered and reused, reducing the need to extract new resources and minimising waste.

The recycling process for lithium-ion batteries includes the following steps:

- Collection: Used batteries are collected by recycling centres, dedicated collection points or take-back schemes.

- Sorting: Not all lithium ion batteries are the same and therefore need to be separated by chemical type in order to ensure a high quality of the recovery activity.

- Disassembly: Batteries are disassembled to separate components and materials. This step may include removal of the outer shell, circuits and metal contacts.

- Inertisation: An inertisation process is carried out to ensure maximum safety in subsequent processing steps.

- Crushing: Battery cells are crushed to separate active materials (cathodes, anodes and electrolytes) and other components.

Separation and - Purification: The separated materials are then subjected to separation and purification processes to isolate lithium, cobalt, nickel and other valuable elements.

- Reuse and Refining: Recovered elements and materials can be reused in the production of new batteries, electronic products and other industrial applications after appropriate refining processes.

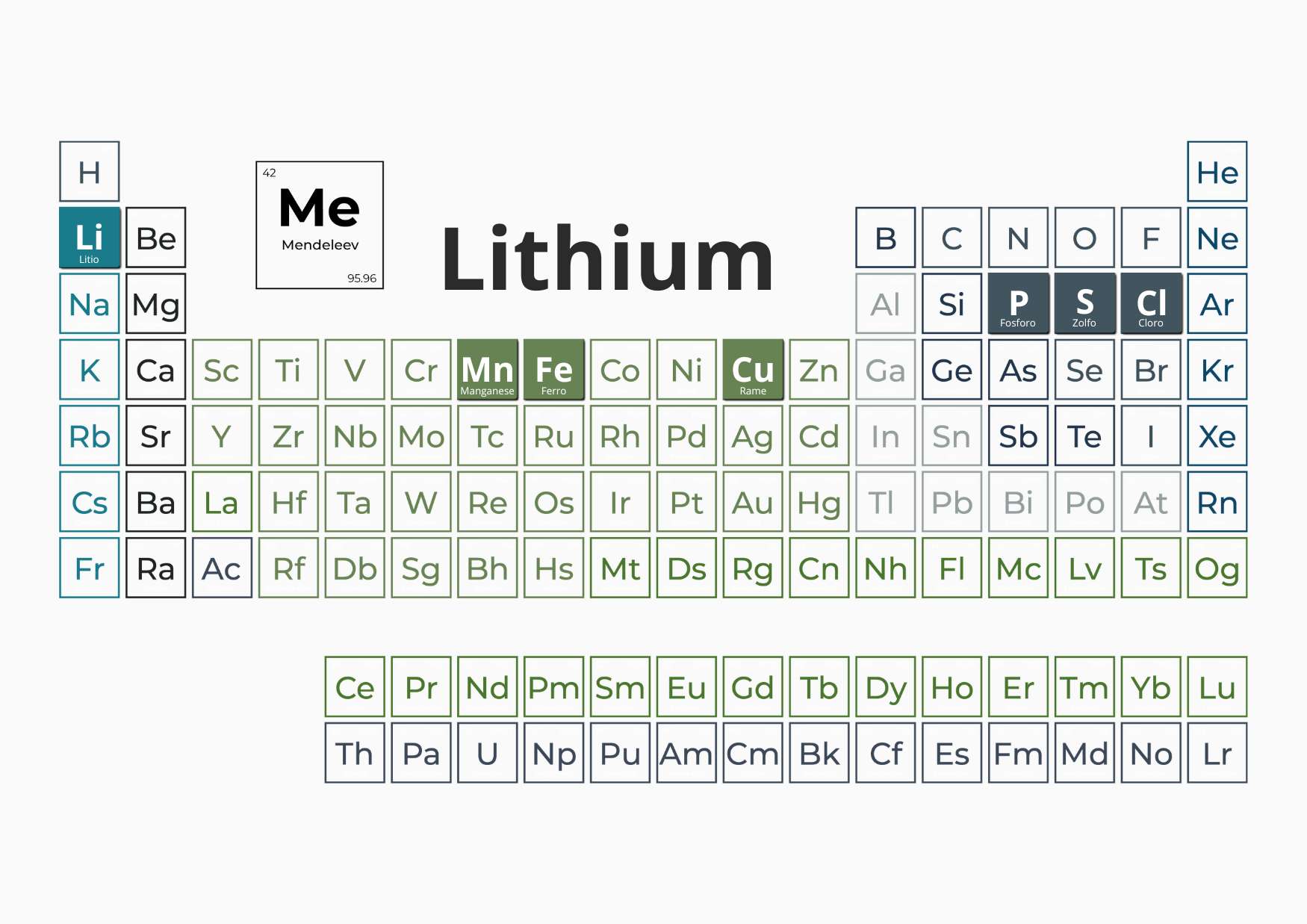

Lithium battery recovery

Primary lithium batteries, often referred to as non-rechargeable lithium batteries, are designed for a single life cycle and cannot be recharged. These batteries are commonly used in devices such as gas meters, clocks, calculators and other consumer electronics.

Although primary lithium batteries do not contain valuable elements like lithium-ion batteries, they do contain chemicals and metals that can be harmful to the environment if not disposed of properly.

Recycling primary lithium batteries allows these materials to be recovered and processed safely, reducing the risk of pollution and negative impacts on public health. The recycling process for primary lithium batteries is less complex than for lithium-ion batteries and includes the following summary steps:

- Collection: Used batteries are collected by recycling centres, dedicated collection points or take-back schemes.

- Safe Processing: Batteries are processed safely to prevent contamination of soil, water and air. This may include treatment of batteries to neutralise hazardous chemicals and separate non-recyclable materials.

- Material recovery: In some cases, it is possible to recover small quantities of metals such as lithium, manganese and iron from primary lithium batteries through recovery processes.

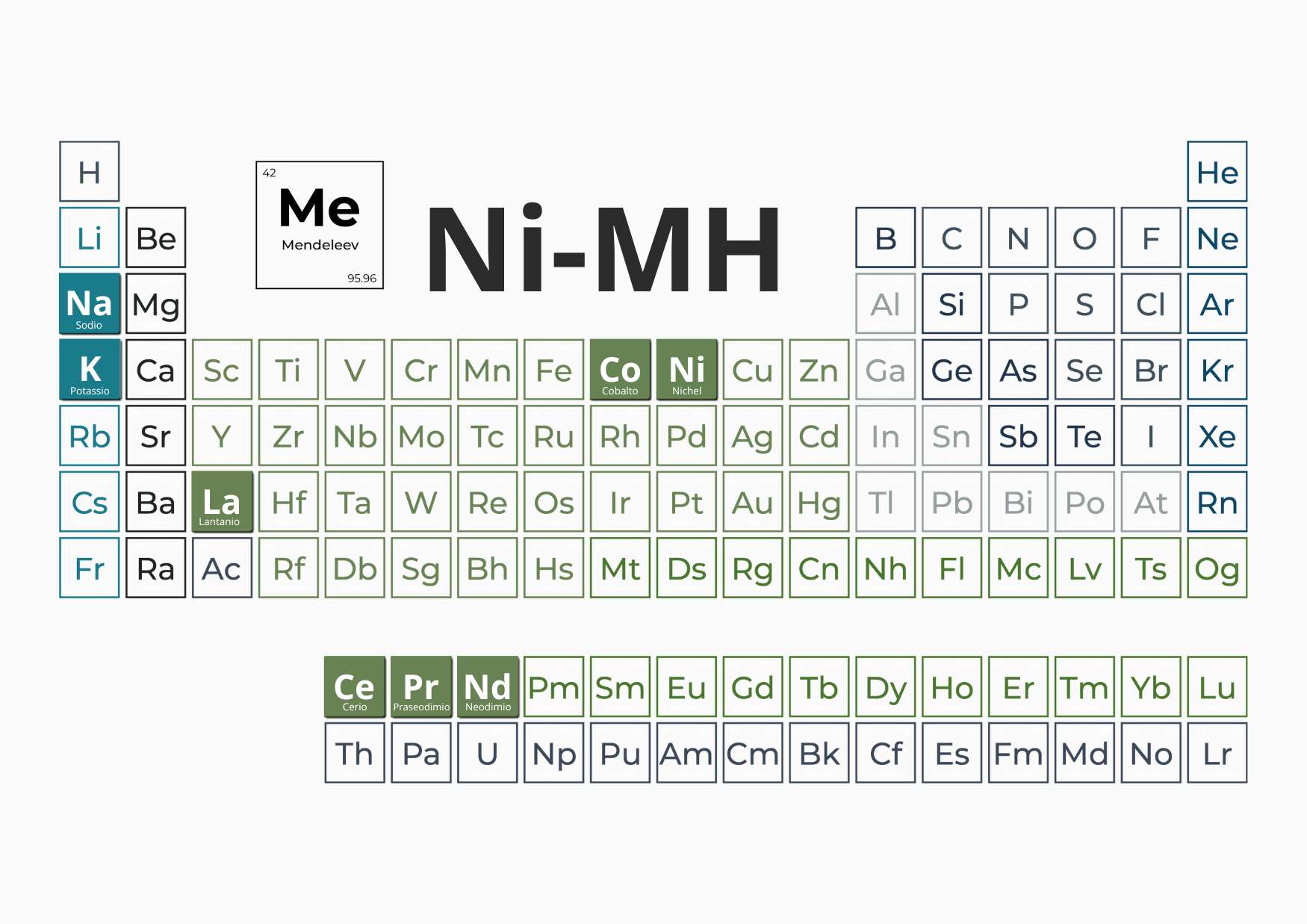

NiMH battery recovery

NiMH batteries contain materials such as nickel, cobalt and rare earths, which are valuable and can be recovered and reused.

Recycling NiMH batteries reduces the need to extract new resources, minimises waste and prevents environmental pollution.

The recycling process for NiMH batteries is very similar to that used for Li-Ion batteries.

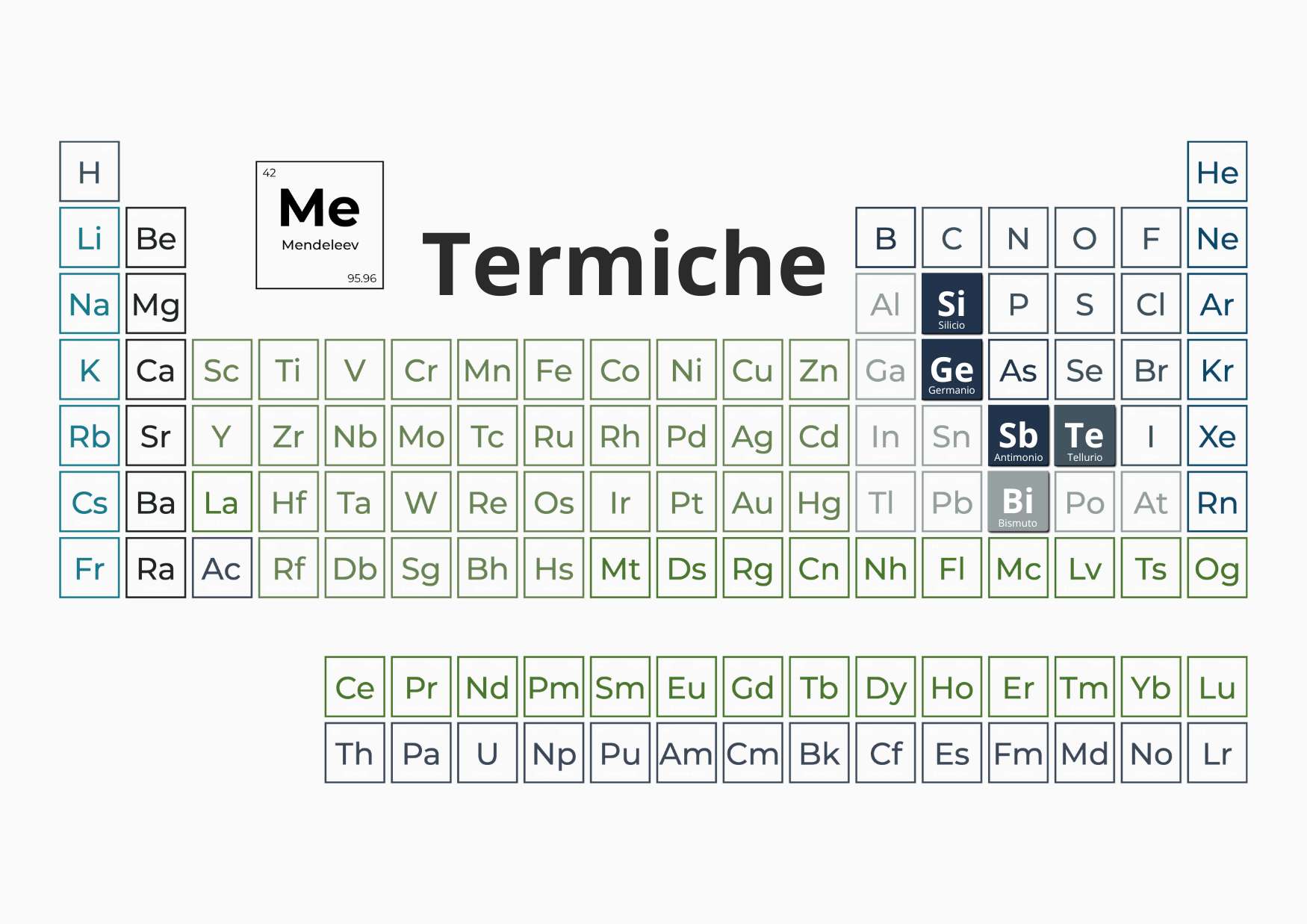

Recovery of thermal batteries

Thermal batteries, or thermoelectric batteries, are devices that convert temperature differences into electrical energy using the principle of the Seebeck effect.

These batteries are particularly used in specialised applications, such as power generators for satellites, remote sensors and portable heating and cooling systems.

The recovery of thermal batteries is a complex and specific process, as these batteries contain unique materials and technologies compared to conventional lithium or nickel batteries.

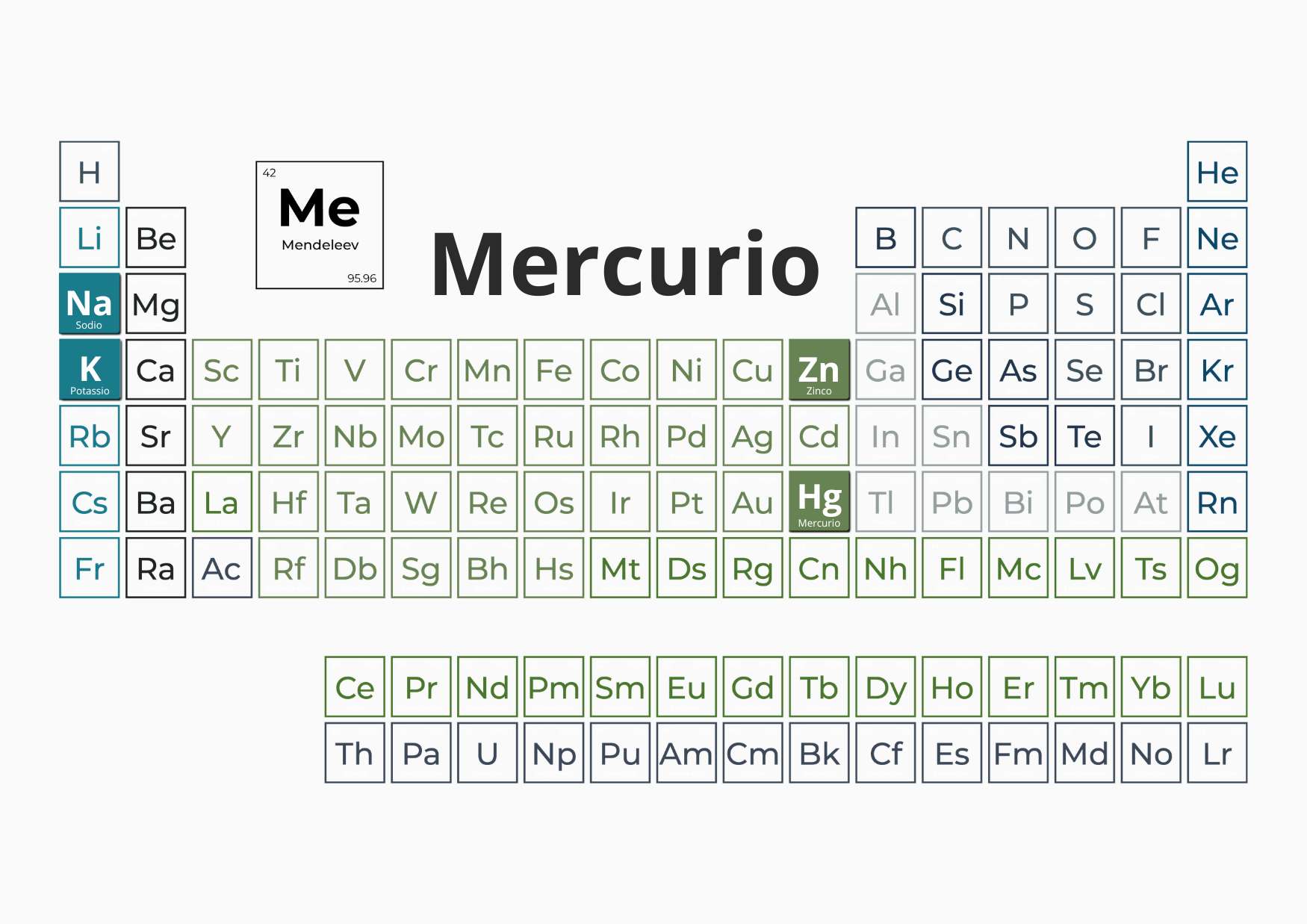

Mercury battery recovery

The recovery of mercury batteries is a particularly delicate and crucial process, as mercury is a highly toxic substance that is hazardous to the environment and human health. Mercury batteries have been widely used in the past in devices such as watches, thermometers, hearing aids and other electronic devices.

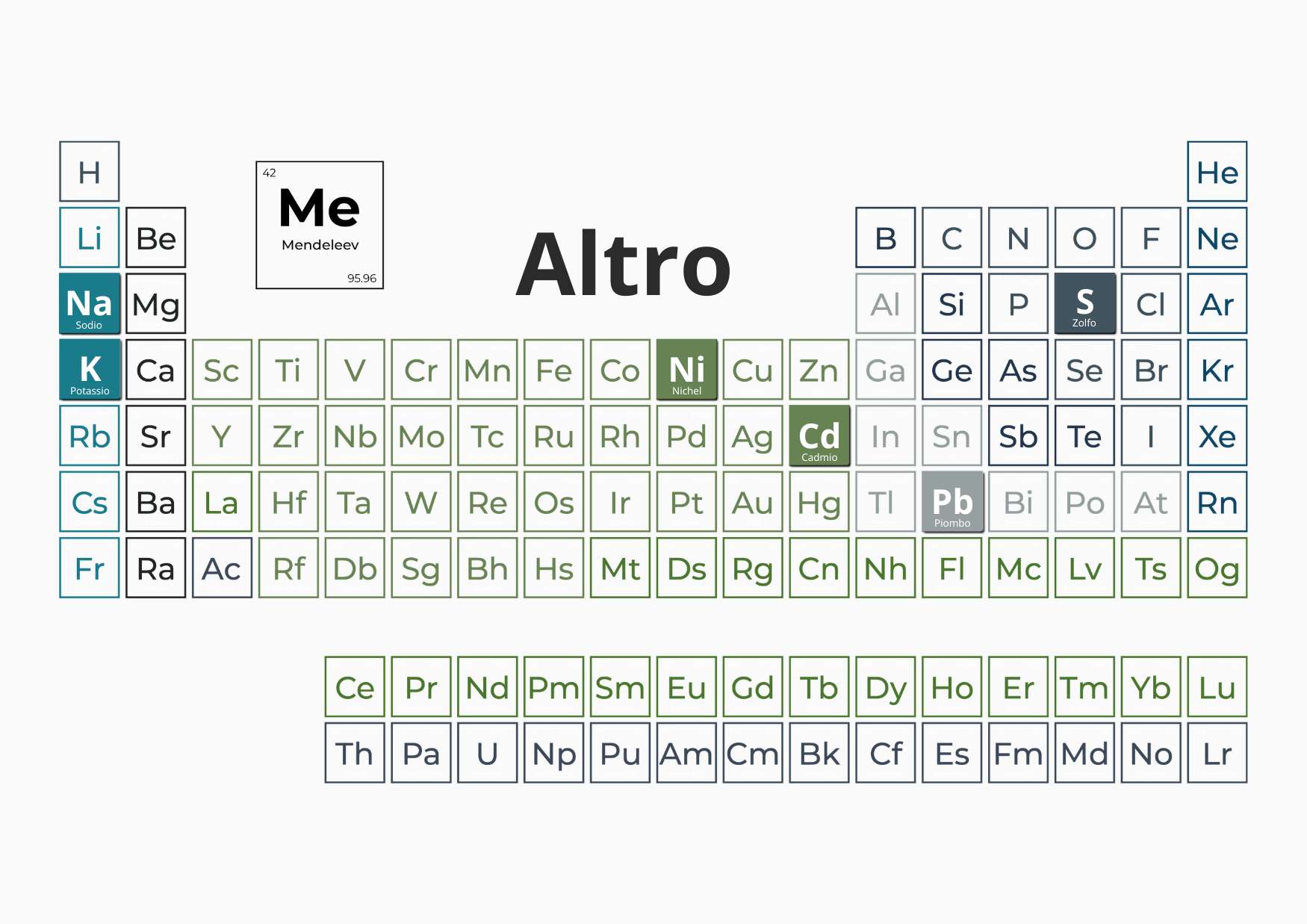

Recovery of other batteries

Every battery can be subject to recovery, regardless of its chemical type (alkaline, lead acid, Ni-Cd, etc.) or field of application. For each situation, Mendeleev is committed to finding the best solution to ensure proper waste treatment and compliance with current regulations.